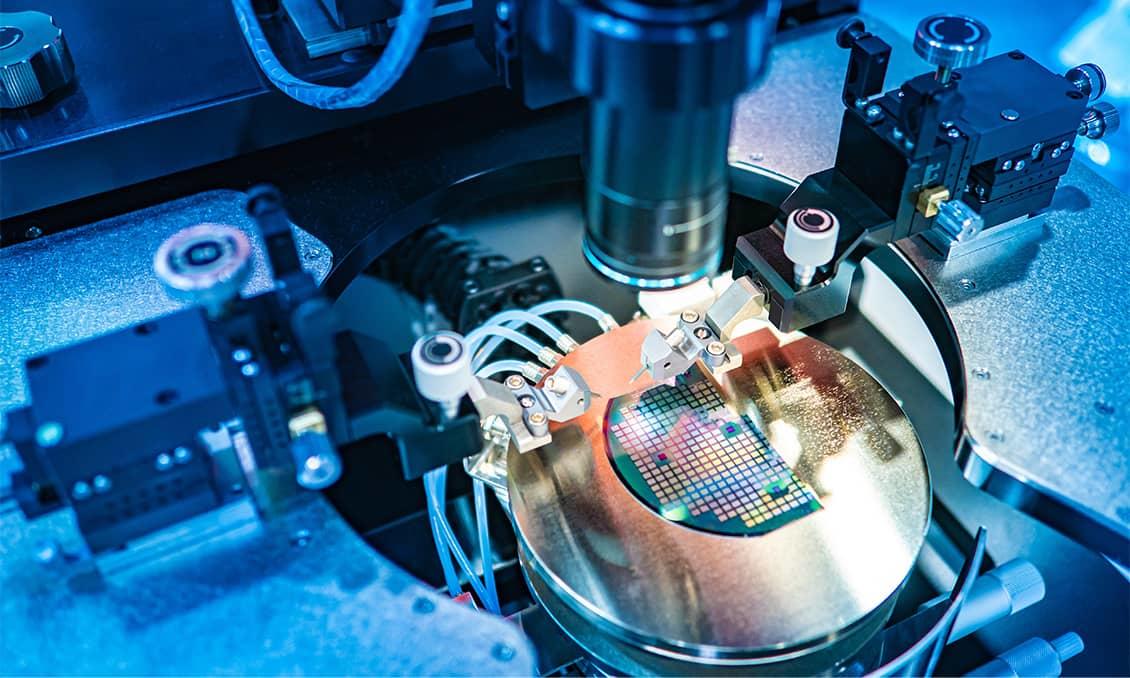

By adding a conductive material to zirconium oxide, we created a ceramic that has the optimal surface resistivity against static electricity.

This ceramic slowly eliminates any charge of static electricity. Therefore, it is used for jigs and other components in production lines to take advantage of how it prevents electrostatic damage and erroneous suction of products from static electricity.

Our Zirconia Ceramics for ESD Protection maintain the outstanding mechanical properties of zirconia, and have extremely stable semiconductive properties (volume resistivity) even inside the product. They protect electronic and semiconductor device parts from electrification problems caused by contact/separation.

Features

- High strength and stable semiconductive material

High strength and optimal resistivity value can be selected from material variations with stable semiconductive property (volume resistivity: 105 to 109Ω). - Supports high-precision complex shapes

Press molding, injection molding, cutting, and a high-precision grinding process make it possible to support a wide range of shapes from simple to complex. - Metal assembly by conductive bonding technology

Proprietary conductive adhesion technology* supports product assemblies that are ceramic and metal.

*According to a survey by Kyocera (as of August 25, 2022)

High strength ESD material

Materials with low surface resistivity tend to have low strength due to the effects of additives. However, Kyocera has developed a new material that meets the demand for increased strength associated with the miniaturization and thinning of parts.

Relationship between flexural strength (3-point bending) and surface resistivity of Kyocera's zirconia materials

Application Examples

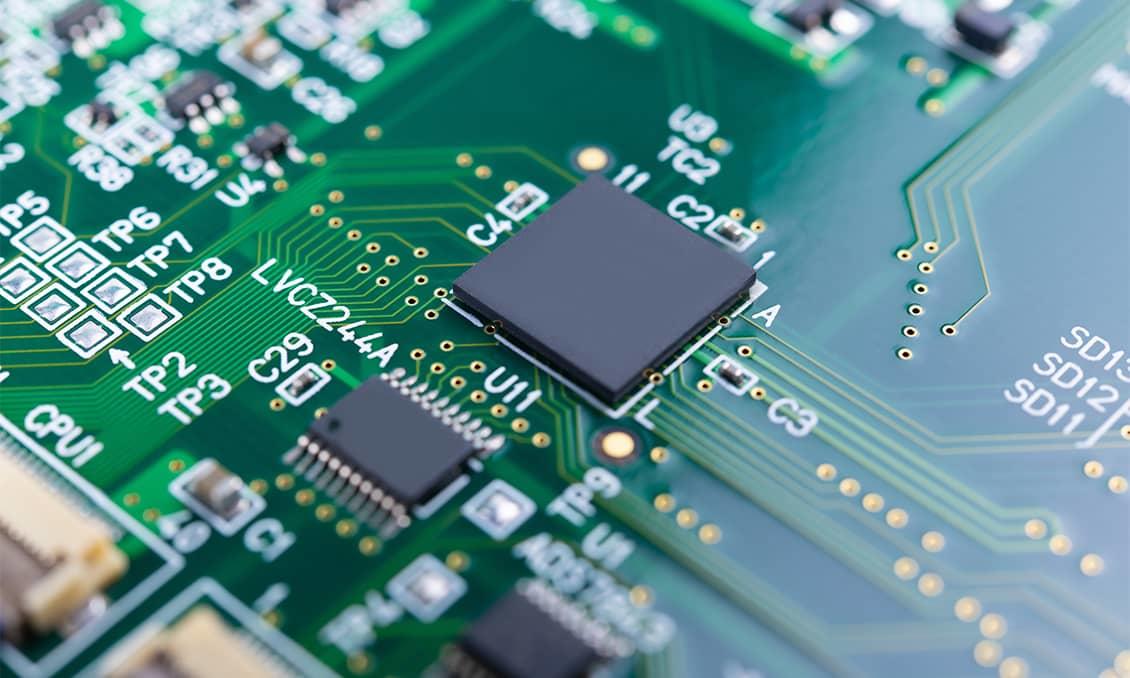

Electrically conductive zirconia ceramics are used in manufacturing processes that require ESD protection and wear resistivity (hardness) for electronic device parts, semiconductor processing parts, etc.

(Suction nozzles for transportation, jigs for slicing equipment, tweezers for inspection, etc.)

-

Suction nozzle for transportation

-

Jigs for slicing equipment

-

Tweezers for inspection

Tip of suction nozzle for transportation

This is an example of the shape for the tip of the suction nozzle for transportation.

Shape Samples

*This is an example of manufacturing with material code Z21H12 or Z21H14.

*We can also support shapes other than those above.

* For round-hole shaped products, high-precision processing of Φ0.020±0.003 is also possible by polishing.

*Conductive adhesion with metal parts is also possible.

Conductive Adhesion Technology

The electrostatic properties and charge transfer rate of a material depend on its surface resistivity. In general, semiconductive materials are not prone to be charged. However, when they are charged, there is a possibility of electrostatic breakdown.

Kyocera is capable of metal assembly based on our proprietary conductive adhesion technology* and many years of experience, and we can solve various problems related to static electricity.

*According to survey by Kyocera (as of August 25, 2022)

■ When no conductive adhesive is used

■ When conductive adhesive is used

Property Data Comparison

Comparison of main properties of Kyocera's Zirconia Ceramics for ESD Protection and other materials

| Material Material Code |

ESD Protection Zirconia | |||||||

|---|---|---|---|---|---|---|---|---|

| Z21H04 | Z21H05 | Z21H07 | Z21H12 | Z21H14 | ||||

| Color | Black | Black | Ivory | Black | Black | |||

| Density | g/cm3 | 5.6 | 5.8 | 5.7 | 5.7 | 5.7 | ||

| Mechanical Properties | Vickers Hardness HV9.807N | GPa | 10.8 | 12.4 | 7.8 | 12.4 | 12.4 | |

| Flexural Strength (3-point Bending) | MPa | 740 | 685 | 600 | 1,000 | 1,175 | ||

| Young’s Modulus | GPa | 210 | 210 | 200 | 220 | 220 | ||

| Thermal Properties | C.T.E | 40~400℃ | × 10-6/K | 10.3 | 10.4 | 9.2 | 10.8 | 10.4 |

| Thermal Conductivity | 20℃ | W/(m・K) | 3.0 | 3.9 | 3.5 | 4.0 | 4.0 | |

| Electrical Properties | Surface Resistivity Value | Ω | 108-109 | 106-107 | 107-108 | 106-107 | 106-107 | |

| Volume Resistivity | 20℃ | Ω・cm | 107-109 | 105-107 | 106-108 | 105-106 | 105-106 | |

| Material Material Code |

Silicon Carbide (SiC) | Alumina | Stainless Steel | |||||

|---|---|---|---|---|---|---|---|---|

| SC211O | SC1000 | AO442O | SUS304 | |||||

| Color | Black | Black | Dark Brown | - | ||||

| Density | g/cm3 | 3.2 | 3.16 | 3.7 | 7.93 | |||

| Mechanical Properties | Vickers Hardness HV9.807N | GPa | 22.0 | 23.0 | 9.6 | 6.4 | ||

| Flexural Strength (3-point Bending) | MPa | 600 | 500 | 245 | 519 | |||

| Young’s Modulus | GPa | 430 | 440 | 284 | 206 | |||

| Thermal Properties | C.T.E | 40~400℃ | × 10-6/K | 3.7 | 3.7 | 7,4 | 10,4 | |

| Thermal Conductivity | 20℃ | W/(m・K) | 60 | 200 | 12 | 26 | ||

| Electrical Properties | Volume Resistivity | 20℃ | Ω・cm | 105 | 108 | >109 | 10-3 | |

*Representative values based on results of internal measurement.

* Z21H07 is a non-magnetic material.

Volume Resistivity

Examples of Kyocera's Zirconia Ceramics for ESD Protection and other materials.

By selecting the appropriate material from among the static diffusive areas according to the application, it is possible to greatly reduce damage and breakage of parts during manufacturing.

Measuring Method

Surface Resistivity Value (Impact of surface finishing conditions)

Kyocera changed the surface finishing conditions and the depth from the surface for our Zirconia Ceramics for ESD Protection, and then measured the surface resistivity value.

Since volume resistivity is extremely stable even inside the product, the surface resistivity value is also stable regardless of the depth from the surface layer and surface specifications.

Measurement Condition

| Measuring Equipment: | Super Insulation Meter "SUPER MEGOHMMETER, SM-8220" (made by HIOKI) |

| Material: | Zirconia Z21H07 |

| Size: | 72 x 48 x 5(mm) |

| Processed from block | |

Surface Resistivity Value (Impact of heat treatment)

We heated our Zirconia Ceramics for ESD Protection at 600°C and then cooled it for one hour. We repeated this process for two cycles and measured the surface resistivity values at nine different points for each cycle.

There is no change in the surface resistivity value even after heat treatment, and the ceramics are extremely stable.

Measurement Condition

| Measuring Equipment: | Super Insulation Meter "SUPER MEGOHMMETER, SM-8220" (made by HIOKI) |

| Material: | Zirconia Z21H07 |

| Size: | 50 x 50 x 5 (mm) |

| Processed from block | |

Measuring Method

*Similar to general zirconia materials, there are cases where mechanical properties are impacted when used under high-temperature conditions. Contact us for details.

Please feel free to contact us if you are considering high-strength, high-wear resistant ESD protection parts and jigs required in the electrical, electronic, and semiconductor fields.

All values listed on this page are representative values obtained from in-house measurements,

and do not constitute guaranteed product specifications.